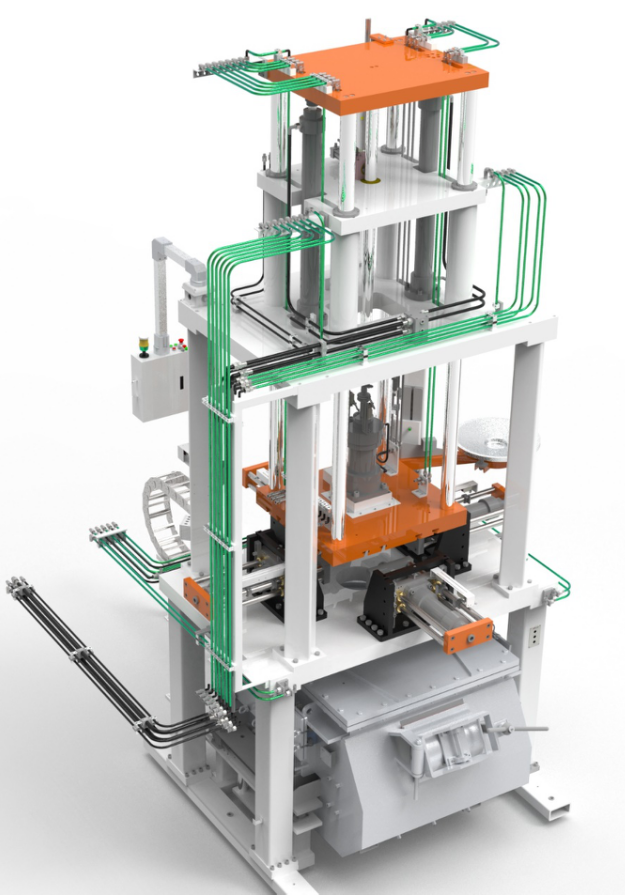

LPDC Machine

WF2516 LPDC machine combines over 20 years’ experience from Wanfeng aluminum alloy wheel casting process, which is suitable for aluminum alloy wheel production. Stable running performance, high efficiency, high precision and easy maintenance are its advantages.

Three low:

1.Low failure: low equipment failure (standardized processing, reducing human factors)

2.Low energy consumption: low energy consumption of equipment (servo hydraulic, exhaust heat storage device and other energy-saving technologies)

3.Low cost: low equipment use cost (long service life of accessories)

Three high:

1.High efficiency: high labor efficiency (compact structure, fast speed)

2.High quality: high quality products (imported configuration, high pressure oil cylinder, patented technology)

3.High rigidity: strong rigidity of the equipment (multi-layer superimposed structure, double main cylinders, central top cylinder penetrating type, reduce the height of the equipment, and enhance the rigidity)

LPDC Machine parameters

|

Item |

Unit |

Parameters |

|

Total height |

mm |

6800 |

|

Moving platen size |

mm |

2500x1600 |

|

Fixed platen size |

mm |

1100x1000 |

|

Free space between columns |

mm |

1500x1095 |

|

Moving platen distance |

mm |

530-1630 |

|

Ejection stroke |

mm |

100 |

|

Cylinder open force of moving platen max |

kN |

188 |

|

Cylinder lock force of moving platen max |

kN |

131 |

|

Ejection force max |

kN |

241 |

|

Cylinder open force of side core max |

kN |

94 |

|

Cylinder lock force of side core max |

kN |

65 |

|

Holding furnace capacity |

kg |

800kg(Bath type holding furnace) |

|

Heating power of holding furnace |

kW |

30 |

|

Extraction tray size |

mm |

φ700 |

|

Extraction tray load |

kg |

30kg |

|

Upper mold cooling arrangement |

pcs |

10 Water air mixing |

|

Below mold cooling arrangement |

pcs |

10 Water air mixing |

Advantages of low pressure die casting machine

The casting crystallizes under pressure, with compact structure and good mechanical properties; Another feature of low-pressure die casting is that one riser is used to connect the mold directly with the furnace. Under the action of pressure, it can be cast directly without riser and the gate is very small. Therefore, the utilization rate of metal is very high.

Project case - LPDC production line